Q: How to deal with the complains if happens? For long term business DALON have more advantage terms for payment. Advance 50% and balance against copy of shipping B/L. If item need open tooling, consider extra 7days. Stock items could be delivered within 3days. DALON usually effect delivery within 21days after advance payment. Tooling charge is one off when first order, all future orders would not charge again even tooling repair or under maintaince. DALON can supply the samples for FREE, but the customers have to support the tooling cost if have and the courier cost DALON have ISO9002 quality system and in-house inspection by Bubble Test Equipment, CMM, Hardness Tester, Roughness Tester, Salt Spray Tester, Tensile Strength Test, Caliper, Micrometer, Height Gauge, Ring and Plug Gauge, Pin Gauge, etc. DALON have R&D and can offer special design about your requirements with drawing 3D in format IGES/STEP, PDF/ CAD in DGW/DXF & photos. Usually we will sign NDA before all drawing and samples. DALON will NOT release your design to any third parties without your permission. Q: Will drawing or sample design safe after DALON get it? Yes, DALON can offer OEM / ODM manufacturing Finally drain and dry the self-lubricating bearings. Then cool down in an oil bath back to room temperature.

Re-Impregnation need Immerge during one hour the parts in an oil bath heated at a temperature between 60☌ and 120☌, depending on oil viscosity. De-impregnation required Degrease and wash in appropriate solventĮliminate the lubricant in a furnace heated around 400☌ for 40 minutes under a neutral atmosphere such as N2, or with reducing agent such as N2 + H2 Standard impregnating oil conforms to SAE 30 specifications Lubricants are suitable for the temperature range from -40☌ to 150☌ Also have option for customer to made special oil impregnation byself Shaft hardness and surface roughness and other parameters such as working temperature and type of lubrication, etc. To select the proper material for a given application, it is necessary to check the maximum values of the material characteristics in comparison with: The metallic structure of the self-lubricating bushing can be made from a wide range of bronze or iron based alloys. Startup friction causes these porous sintered bronze bushing to release a thin layer of oil on the bearings surface.ĭALON sintered bronze bushing Properties (SAE841):Ĭoefficient of thermal expansion ( at +23☌) Flanged sleeve bearings handle both radial and thrust loads. Radial loads are perpendicular to the shaft. which resulting in a very low friction coefficient and maintenance-free for general engineering applications.Īll plain bearings are designed to handle radial loads, thrust loads, or a combination of the two. The oil contained in the porosity provides a constant lubrication between bearing and shaft, the system does not need any additional external lubricant, allows this type of sintered bronze bushing to work under hydrodynamic conditions. All Rights Reserved.DALON sintered bronze bushing Introduction:ĭALON self-lubricating sintered bronze bushing are manufactured of pressed copper and tin powders by sintered technology and impregnated with lubricating oil and high porosity (20-25% in volume). © DANDONG FUDING ENGINEERING MACHINERY CO., LTD. As I know, most of iron foundries in China do not have this Some buyers will require V Charpy Impact Test to get the impact As for theĬomparison between these two standards, please check our blog. Required the Rockwell hardness as the standard. Too high may cause the hard spotsĭuring machining, too low will affect the application. As usual, the Brinell Hardness fromġ60-220 should be a good range.

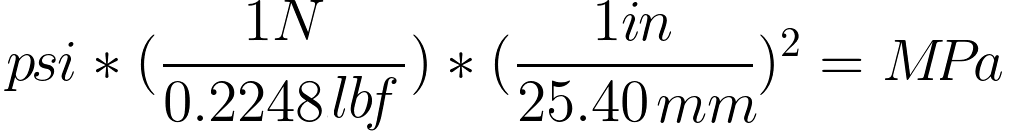

As for the ductile iron 60-40-18,įor the machined parts, the hardness should not be too high toĪffect the machining process. Therefore, they will not be broken easily. Which means they have better ductility or called as malleability. High elongation means the iron casting can be pulled to longer, As for the ductile iron 60-40-18, its yield strength is Strength has already covered the most of requirements to the It just more deeply measure the strength of cast iron. It is not very necessary to check this property since 414 Mpa tensile strength.ĭefine the strength of cast iron, I do not talk about its real Parts need to use this material, then your supplier should keep Of 60000 psi, therefore, it is equal to 414 Mpa. For example, the ductile iron 60-40-18 has tensile strength Strength will show the strength of cast iron when it is pulled untilīroken. In China, herein I listed some main chemical properties for the According to my personal experience in Dandong Foundry ┆ About Us ┆ Casting Products ┆ Casting Workshop ┆ Machining Workshop ┆ Inspection ┆ Certificate ┆ Blog Articles ┆ Contact Us ┆ Cast Iron Mechanical Properties - Dandong Foundry

0 kommentar(er)

0 kommentar(er)